In all, the waste plastic power plant generated a net power of 216.461KW at an equivalence ratio of 1.5. To achieve proper energy optimization, the high temperature flue gas obtained from the gas turbine after pressure loss was passed through a “Heat Recovery Steam Generator” that allowed water at 25☌ to be heated up to produce steam which in turn drove a steam turbine to generate electricity of 255.3KW.

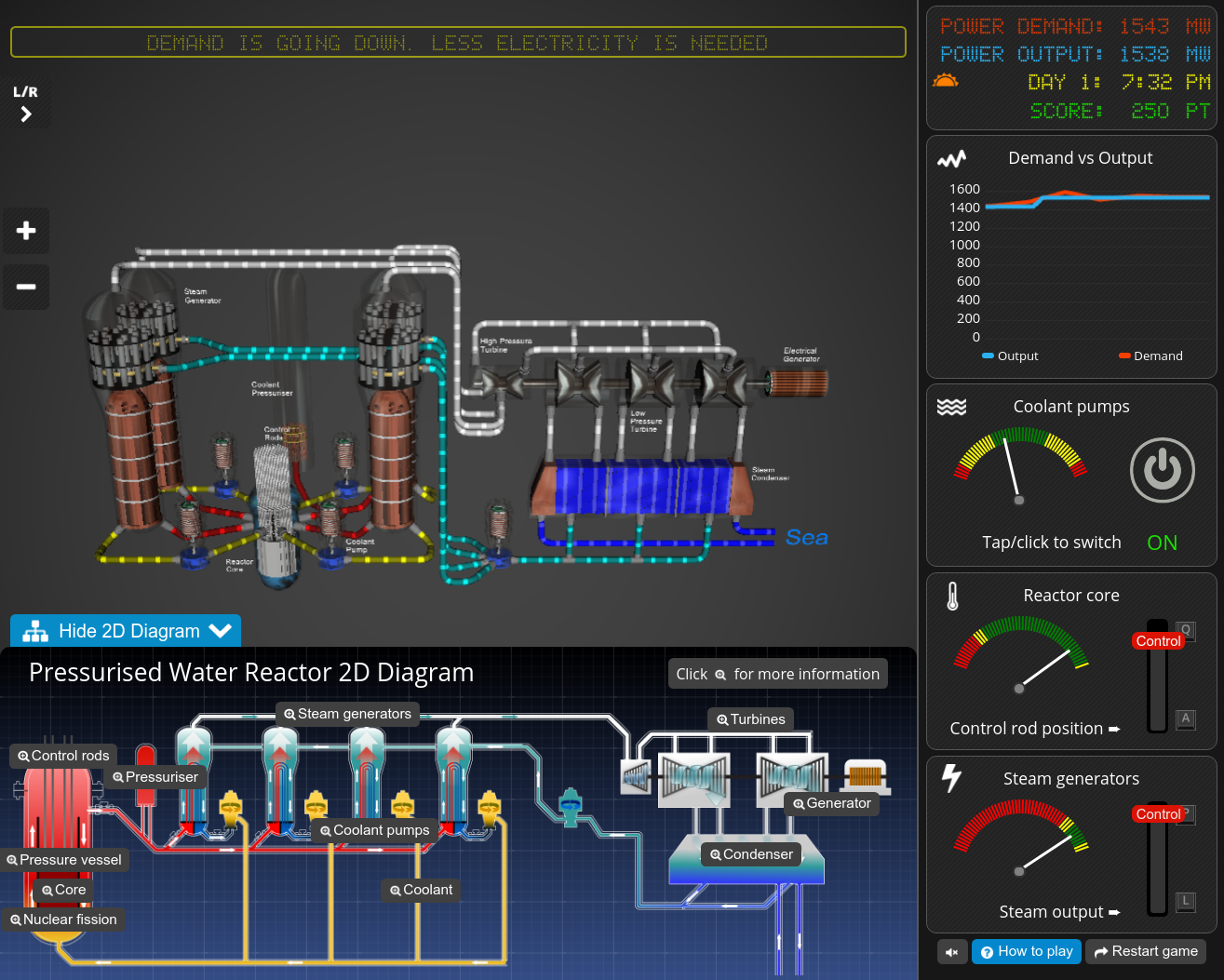

POWER PLANT SIMULATION SIMULATOR

Nuclear Power Plant Simulator is addictive. Unfortunately, TRNSYS requires very detailed input data to get results that accurately reflect expected plant performance. Nuclear Power Plant Simulator is a fun way to learn how atomic energy works and what happens in the control room.

POWER PLANT SIMULATION SOFTWARE

TRNSYS is a commercially available software package and is very suited for modeling complex systems, such as parabolic trough power plants. Take part in an educational excursion to the Ignalina Nuclear Power Plant Control Room simulator The simulator fully imitates the real plants Control Room at the time of the Units shutdown, as of December 31, 2009.

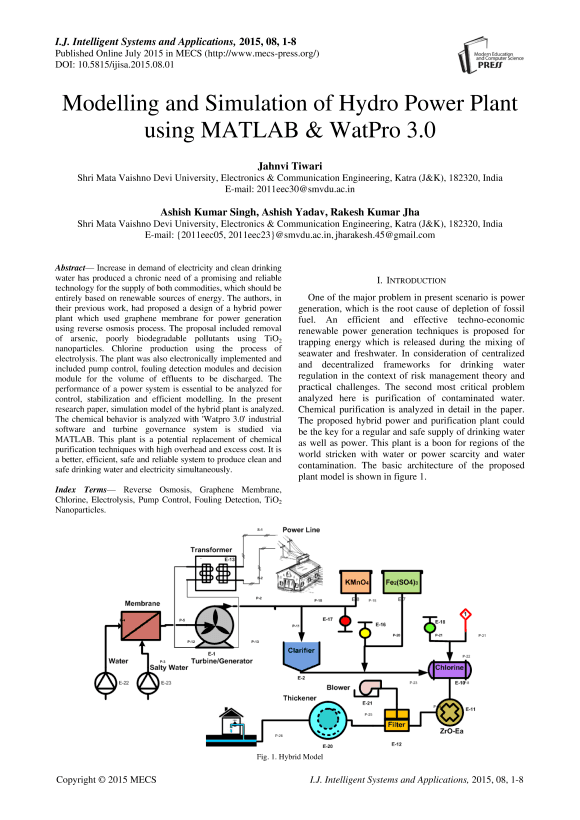

In this reactor, the gaseous fuel burned with excess air in the combustion chamber to produce a high temperature and pressured gas that drove the gas turbine (modelled as an expander) to generate electrical power of 1194KW. simulation software, to model parabolic trough solar power plants 5. Modelling and Simulation of Thermal Power Plants Mathematical modelling and simulation are important tools when dealing with engineering systems that today are becoming increasingly more complex.

POWER PLANT SIMULATION FREE

After cooling of the top product and separation to obtain the volatile gaseous fuel from the liquid fuel oil, the volatile gaseous fuel alongside air were pressurized with a compressor and then combusted in a Gibbs free energy reactor. The pyrolysis reactor modelled as a conversion reactor was used to thermally crack 2000Kg/h of HDPE feed at a temperature of 450☌ to produce a top product containing a mixture of liquid fuel oil and volatile gaseous fuel. A heat transfer fluid flows in the focal line of the troughs collecting solar heat, which is transferred to high pressure water from. The plant includes numerous parabolic trough collectors tracking the sun on a single axis. A simulation model that produces electricity from the High Density Polyethylene (HDPE) waste plastics has been developed using Aspen Hysys process simulator. A detailed model of a real solar thermal power plant has been built using a steady-state power plant simulation software. This paper presents a theoretical framework for the simulation of waste plastic power plant. Where recycling becomes an issue, technologies that utilize the waste plastics to generate electricity can be employed. Non-recyclable plastic materials are used in areas like packaging, 3D printing, and construction. The recovery of this abundant energy helps to curb environmental concerns associated with plastic utilization. The high energy content of plastics can be converted to electricity.

0 kommentar(er)

0 kommentar(er)